Hospital

Ookuramaya Memorial Hospital

Optimization of the thermal system

They are well known in the local community as a community-based hospital since 1963. In 2010, they joined the Yokohama Medical Group and are actively developing follow-up services for patients through cooperation among hospitals.

Reason for Selection

Understand where heat is going and use it effectively

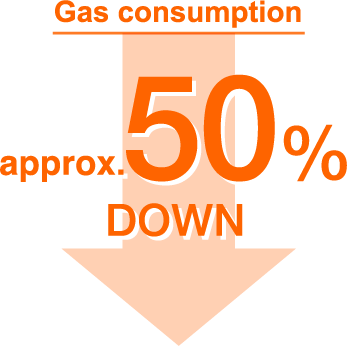

We used to use NTEC’s competitor steam boilers for hot water supply, heating and cooling, and autoclaves. However, with the introduction of individual air conditioning and the electrification of the autoclaves, steam was used only for hot water supply. NTEC proposed a change to a hot water system that did not use steam, and after considering the possibility of cutting our gas costs by about half, we decided to go with the hot water system. The reduction in fuel costs was not only just as estimated, but it also gave us more space to expand our rehabilitation room, which in turn allowed us to provide more comprehensive rehabilitation services to our patients.

NTEC’s Proposal

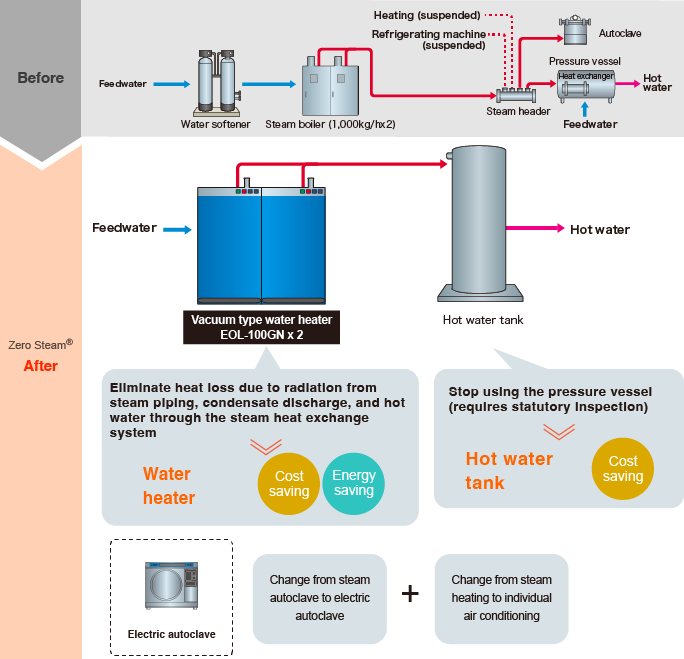

System conversion from

steam to hot water

Zero Steam®

Energy and cost savings by converting steam system to hot water system

The conventional steam system was used only for hot water supply, and there was a waste in discarding excess heat from the steam. Therefore, we proposed them a hot water system that directly supplies hot water. The system can save energy and cost without changing the use of the hot water. The EOL-100 is compact, highly efficient, and easy to operate.

Effects

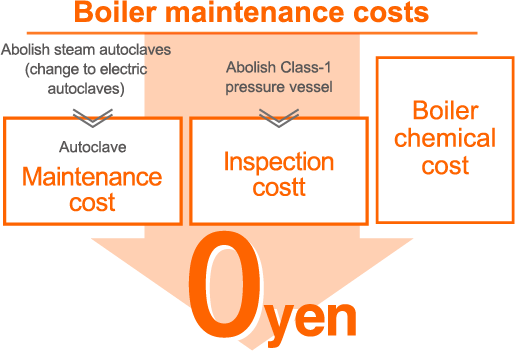

When heat (steam) is used only for hot water supply, it is optimal to convert the steam system to a hot water system. By converting to a hot water system, they have eliminated heat loss due to sensible heat from steam condensate and blowdown and cut their fuel costs nearly in half. They have also eliminated the need for boiler chemicals and Class-1 pressure vessel inspections required with the steam system, which also saves them money.

Related Products

Vacuum type water heater

Vacotin Heater

● Specification

Output: 116kW

Efficiency : 90%

Healthcare introductions and case studies

-

Japan Blood Products Organization Kyoto Plant

Super EQOS EQi Series

EQi-3000NM -

Thai Nakhon Pattana CO., LTD.

Super EQOS EQi Series

EQi-6001LM