Super Vacotin Heater

GTL/GTLH Series

| Model | Output | Fuel |

|---|---|---|

| GTL-300 | 349 kW | Natural gas Propane |

| GTL-400 | 465 kW | |

| GTL-500 / GTLH-500 | 581 kW | |

| GTL-630 | 733 kW | |

| GTL-800 | 930 kW |

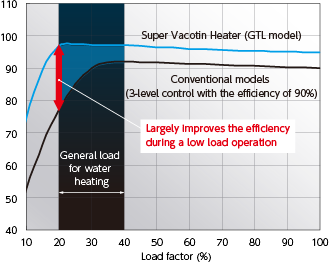

Ultra-high efficiency

The alternate fin water tube arrangement (Patent No. 5788167) improves the heat transfer rate, resulting in a high efficiency of 95%. 5:1 turndown ratio (proportional combustion control) achieves a part-load efficiency of 96% or higher (at 20% load).

NOx emissions of 60 ppm or less (converted to 0% O2)

This model is equipped with an excellent low NOx split-flame burner with self-recirculating combustion. It is a highly environmentally friendly water heater with reduced emissions of NOx gas, a cause of acid rain and photochemical smog.

105%* efficiency through latent heat recovery

It is the world‘s first vacuum type water heater to achieve 105%* efficiency by recovering latent heat from the exhaust gas. The latent heat recovery unit can be retrofitted or bypassed.

* 103% for propane fired

Space-saving design

The GTLH can be carried in by dividing the main unit and the latent heat recovery unit, allowing it to be installed in a location with narrow carry-in routes.

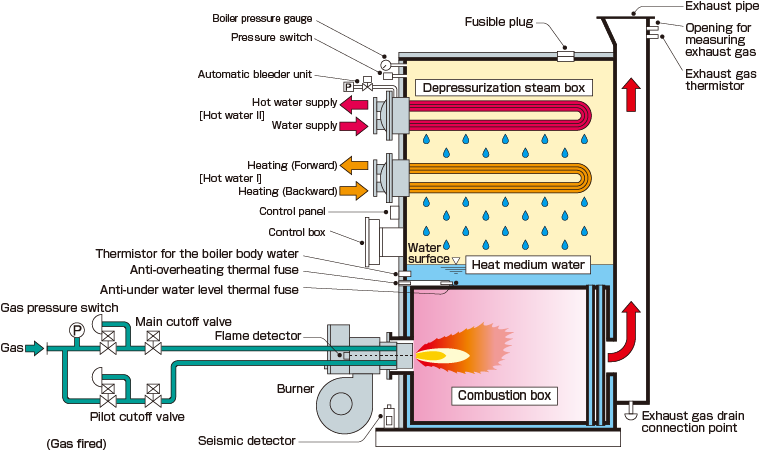

What is a vacuum type water heater “Vacotin Heater”?

It consists mainly of a burner, combustion furnace, water tubes, heat transfer water, depressurized steam chamber and heat exchangers. There is no air inside the boiler body and it is completely sealed from the outside air. The heat transfer water is sealed over the furnace and water tubes, and the depressurized steam chamber is maintained at a reduced pressure below atmospheric so that when the heat transfer water is heated by the burner, it immediately boils, generating steam at the same temperature as the heat transfer water. The steam generated inside the boiler heats the heat transfer water by condensing on the surface of the heat exchangers located in the reduced pressure steam chamber and returns to the heat transfer water as water droplets. In other words, there is a heat transfer water cycle of “boiling, evaporation, condensation, and liquefaction” inside the boiler. Therefore, you don’t have to refill the heat transfer water and there is no risk of heating without water inside the boiler.