Hotel

Kariya Plaza Hotel

Installation of ultra-high efficiency vacuum type water heater (latent heat recovery type)

They are in an excellent location, just a two-minute walk from the Meitetsu/JR Kariya Station. They are a long-established hotel popular with business travelers, individual travelers and groups, with a growing number of repeat guests attracted by their warm hospitality.

Reason for Selection

Approx. 20% energy savings and quick maintenance response

The previous water heater, manufactured by NTEC’s competitor, was installed when our hotel was newly built and was gradually failing more and more due to age-related deterioration. When we consulted with some boiler manufacturers, NTEC replied, “We will respond immediately if anything happens to the water heater!” Their words were very reassuring to us because a stable operation of the water heater is very important for us to make sure that our customers can relax in their baths. We were also concerned about the deterioration of the oil tank, as we used to use a fuel oil-fired water heater. They proposed that we can take advantage of subsidies by converting to gas fuel at the same time as the replacement, and we decided to install an ultra-high efficiency vacuum type water heater (latent heat recovery type). We are satisfied with both the 20% reduction in fuel costs in the first nine months of installation and the peace of mind that comes from the stable operation of the water heater.

NTEC’s Proposal

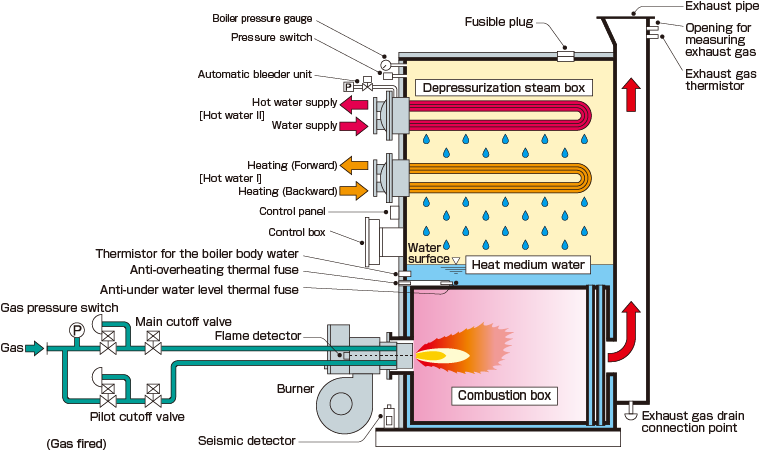

Vacuum type water heater

(latent heat recovery type)

Super Vacotin Heater

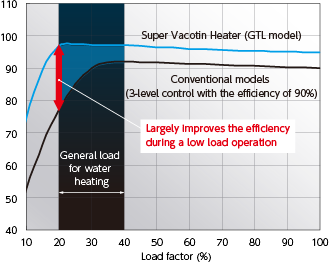

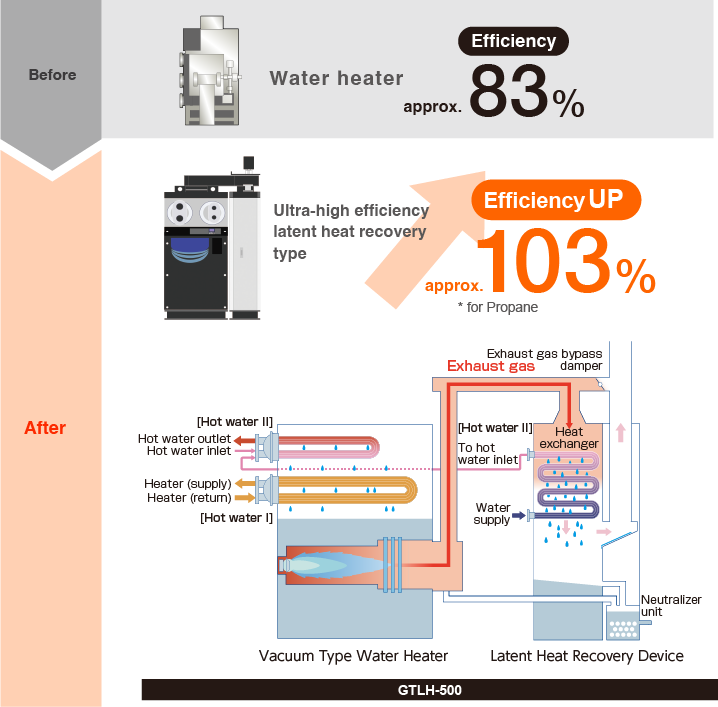

High energy savings with ultra-high efficiency exceeding 100%

They were concerned about the breakdown of aging equipment and how to reduce fuel costs. We proposed the GTLH-500, an ultra-high efficiency vacuum type water heater (latent heat recovery type), and the use of subsidies by converting fuel to gas. The GTLH-500 has an extremely high efficiency of 103% and can also control combustion rate according to the hot water load, achieving outstanding energy-saving effects. In addition, the fuel has been converted to gas, eliminating the need for an oil tank and solving the problem of tank deterioration. We continue to provide a prompt maintenance response for their peace of mind.

Effects

The introduction of vacuum type water heater (latent heat recovery type) has significantly

reduced fuel costs and carbon dioxide emissions, resulting in a lower environmental impact.

Related Products

Vacuum type water heater (latent heat recovery type)

Super Vacotin Heater GTLH

● Specification

Output : 581kW

Efficiency : 105% (103% for propane)