Food & Beverages

Kirin Beer Hokkaido Chitose Factory

Improvement of energy saving and work environment

They produce the Kirin’s flagship brands such as the Ichiban Shibori and the Lager, and are a manufacturing base for the Hokkaido region. The expansive factory is surrounded by greenery and regularly hosts events. They also offer factory tours that allow visitors to see their production facility up close (reservation required). It is a popular spot not only for families, but also for local residents as an “adult social tour”.

Reason for Selection

Heat generation for essential wheat and rice preparation process

Expectation of energy savings and other benefits

Every year, we have taken energy-saving measures for steam boilers, which are the heat generation equipment for boiling wheat and rice, the raw materials for beer. NTEC proposed the “F-nex” system as one of these energy-saving measures. When we heard from them that this system could recover the hot air in the boiler room and use it as thermal energy, we immediately reached a consensus within our company and decided to adopt it. As a result, the energy savings and improvement of the working environment in the boiler room exceeded our expectations. We were also reassured by their prompt response and are impressed by their speedy and accurate proposals as they actually survey the site.

NTEC’s Proposal

Feedwater preheating

system

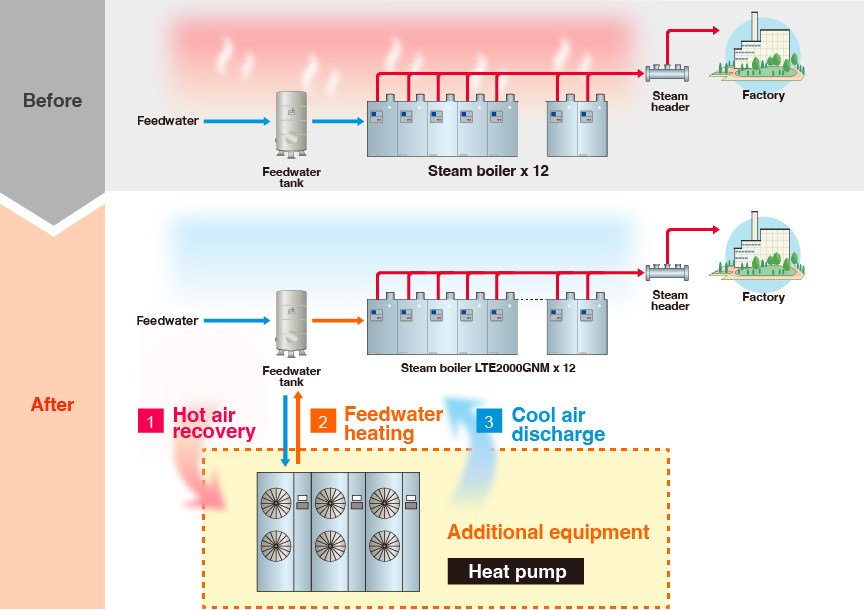

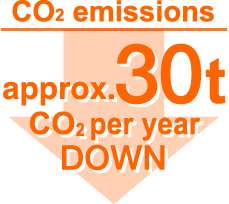

Energy savings and additional improvement by heating feedwater with high-efficiency heat pump

The boiler room was as hot as a sauna. We proposed the “F-nex” system to them, which uses a heat pump to recover the hot air and raise the boiler feed water temperature. As a result, the boiler room temperature has been lowered by effectively recovering the heat and their working environment has been improved.

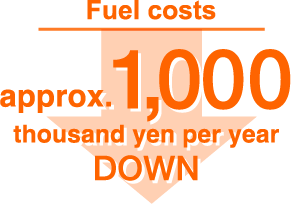

Effects

Improved system efficiency through effective hot air recovery reduces fuel costs and CO2 emissions, and lowers the boiler room temperature, improving the working environment.

Improving the

work environment

in the boiler room

Cool air from the heat pump lowers the temperature in the boiler room and improves the working environment.

Related Products

Feedwater preheating system

Build a high-efficiency system with existing equipment

Factory introductions and case studies

-

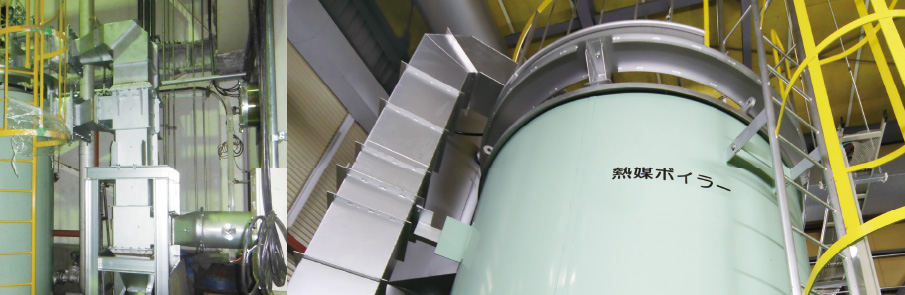

A certain film processing company

Thermo Heater NH Series

NH-100A

Case Studies

Chemical

A certain film processing company

Energy saving of thermal oil boiler

High-temperature processing is required for the production of packaging materials that require high hermeticity, such as food products, and high-performance films used for insulation and protection of substrates, etc.

Thermal oil boilers, which heat and circulate thermal oil at 300°C or higher, are used for such production.

Reason for Selection

Consider energy savings by replacing aging equipment

We had been using a thermal oil boiler since the plant was completed, and it had been breaking down more frequently due to age, so we thought we needed to replace the boiler before a sudden shutdown would affect the production line. In planning for a new boiler with higher efficiency than the existing one, we looked at several manufacturers and chose NTEC after considering all the factors, including their past maintenance support. We had asked them for very strict energy saving requirements, but the results exceeded our expectations and we are satisfied that we made a good choice.

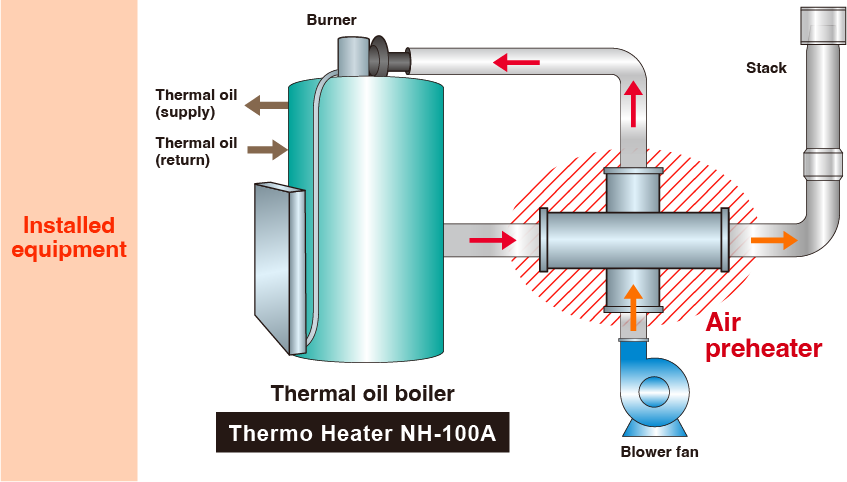

NTEC’s Proposal

Thermal oil boiler

Thermo Heater

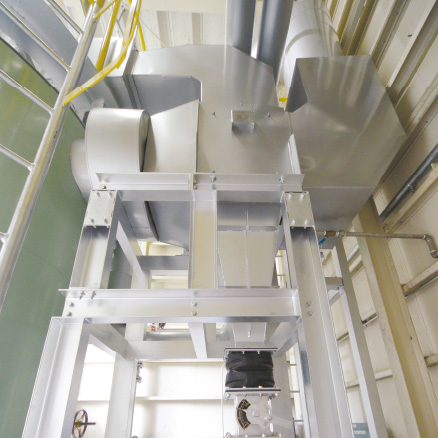

Air preheater to recover heat from exhaust gas for increased boiler efficiency

A thermal oil boiler, which can supply heat at high temperatures that are difficult to supply with steam boilers, is essential for the production of highly functional films. On the other hand, the exhaust gas from a thermal oil boiler tends to be high in temperature, resulting in a large heat loss. In this replacement, we proposed a thermal oil boiler equipped with an air preheater that recovers heat from the exhaust gas. By recovering heat from the exhaust gas and utilizing it for combustion air, the efficiency of the boiler is increased and fuel consumption can be reduced.

They also use our boiler for other production lines, and since they consider the use and importance of the boiler, we propose that they have spare parts for pumps and other important equipment in case of failure, and we also try to provide after-sales service so that they can say “No way! (Already?)” instead of “Not yet?”

What is a thermal oil boiler (Thermo Heater)?

A thermal oil boiler is a boiler that heats circulating thermal oil instead of water. Since the boiling point of thermal oil is much higher than that of water, heat can be supplied at a high temperature of 300℃ at atmospheric pressure. Unlike a steam boiler, a thermal oil boiler doesn’t require water treatment such as water softeners or boiler chemicals. Thermal oil boilers are mainly used in industrial plants that require uniform heating at high temperatures, and for proper heat supply it is very important to control the temperature of the thermal equipment and piping as well as the boiler itself. We have accumulated a wealth of knowledge through our many years of experience, and we can offer boilers suitable for thermal equipment, as well as system design and construction work that can take advantage of them.

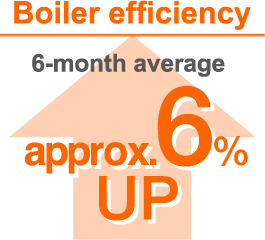

Effects

Thermo Heater (with air preheater)

Due to the high temperature of the thermal oil, the exhaust gas is discharged at a much higher temperature than in a steam boiler. Heat is recovered from the exhaust gas as combustion air, which improves the boiler efficiency.

Significant reduction in fuel costs by air preheater

Related Products

Thermal oil boiler Thermo Heater

● Specification

Output : 1,163kW

Max. working temperature: 300℃

Fuel: LPG

Factory introductions and case studies

-

Kirin Beer Hokkaido Chitose Factory

Feedwater preheating system

F-nex