EQOS Series

| Model | Equivalent evaporation |

Fuel |

|---|---|---|

| EQS-101K | 100 kg/h | Diesel Kerosene |

| EQS-201 | 200 kg/h | |

| EQS-301 | 300 kg/h | |

| EQS-121 | 120 kg/h | Natural gas Propane |

| EQS-161 | 160 kg/h | |

| EQS-251 | 250 kg/h | |

| EQS-351 | 350 kg/h | |

| EQS-402 | 400 kg/h | Diesel Kerosene Natural gas Propane |

| EQS-502 / EQSH-502 |

500 kg/h | |

| EQS-751 / EQSH-751 |

750 kg/h | |

| EQS-1002 / EQSH-1002 |

1,000 kg/h | |

| EQS-1502 / EQSH-1502 |

1,500 kg/h | |

| EQSH-2002 | 2,000 kg/h |

100-350 kg/h

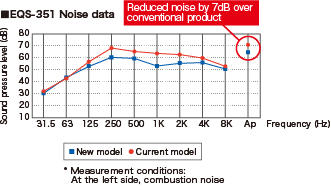

Low noise (-7dB compared to conventional model)

The new intake silencer reduces the blower noise, the largest noise source of boilers. The boiler can be operated at night or early in the morning without worry.

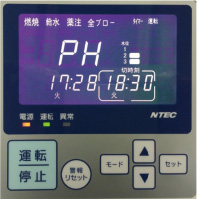

New high-performance microcomputer “V-Navi”

- New display contents: Operation status, error history, and maintenance information are added.

- Hierarchical selection display: Improved operability by displaying items and parameters in a hierarchical manner.

- Multiple remote controls: Multiple remote controls can be attached to a single boiler.

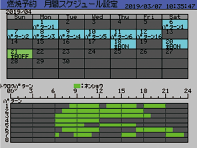

- Operation scheduling: Startup/shutdown down can be done by setting the day of the week and time.

- Boiler water control: Automatic dosing of boiler compound, blowdown instructions, etc.

- Operation data recording: Operating hours, number of operations, operation history, and error history

- Communication function: Remote monitoring available

400-500 kg/h

Industry’s highest level of high-efficiency boiler body

Efficiencies of 91% (Model 402) and 90% (Model 502) are achieved. The high-efficiency model with an economizer (Model EQSH) achieves an efficiency of 97%, the highest in the industry.

New high-performance microcomputer “V-Navi”

High-end model equipped with high-performance microcomputer “S-Navi”

Control: The boiler automatically performs and controls the following functions

- Reduction of combustion frequency

- Purge standby operation

- Steam pressure backup

- Boiler water control

- Multi-interlock

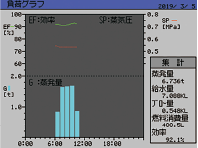

Management: Self-diagnosis and visualization of operating data

- Thermal management data

- Operation control function

- Guidance function

- Combustion scheduling function

- Communication function

750 kg/h

Cartridge-type boiler body significantly reduces replacement costs

The cartridge-type boiler body has two advantages: simple design and reusability. This cartridge design significantly reduces replacement costs and environmental impact.

High-end model equipped with high-performance microcomputer “S-Navi”

1,000-2,000 kg/h

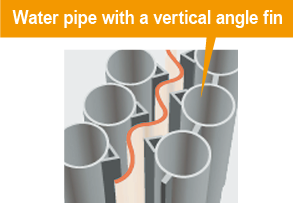

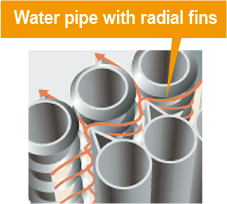

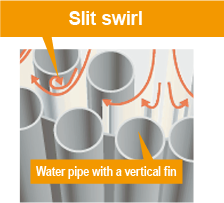

Hybrid heat exchange boiler body “Hi”

Through in-depth analysis of heat exchange in the convection heat transfer section of a boiler body, we have completed a new high-efficiency boiler body (Hybrid heat exchange boiler body “Hi”) by optimizing the combination of three types of fins. The high-speed combustion gas generates intense vortex between the water tube groups, which enhances the heat transfer effect as well as a self-cleaning effect that prevents soot adhesion and growth. This high-efficiency boiler body simultaneously achieves great heat transfer efficiency and durability/stability.