- Gas

- Oil

Super EQOS

EQi / EQO Series

| Model | Equivalent evaporation |

Fuel |

|---|---|---|

| EQi-2000 | 2,000 kg/h | Natural gas Propane |

| EQi-2500 | 2,500 kg/h | |

| EQi-3000 / EQiH-3000 | 3,000 kg/h | |

| EQi-6001 / EQiH-6001 | 6,000 kg/h |

EQi-2000/2500

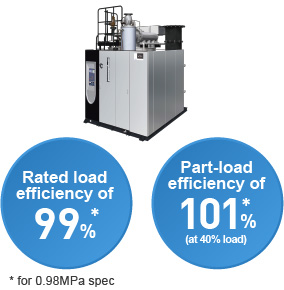

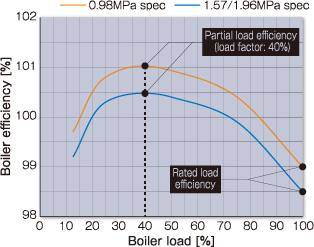

Ultra-high efficiency and power saving

An industry leading boiler efficiency of 99% is achieved through low air ratio combustion.The blower fan speed is controlled by the inverter according to the boiler load to significantly reduce the blower power consumption at low load.

Space-saving design

It is a slim and compact boiler with an installation width of 900 mm, which is one of the smallest in the industry.

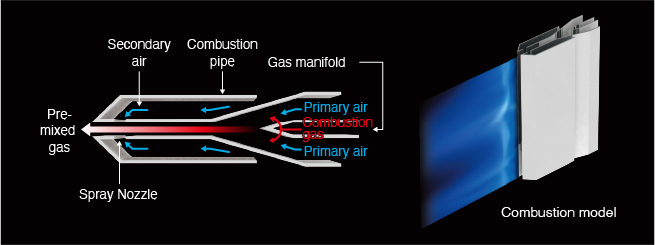

Ultra-low emission combustion

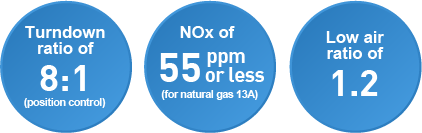

The Jet Film Combustion® technology achieves ultra-low emissions with NOx of 25 ppm and CO of 30 ppm at low air ratio.

EQi-3000/EQiH-3000

Ultra-high efficiency

Low NOx emissions

The pre-mixing split-flame burner achieves NOx of 60ppm or less (converted to 0% O2)

EQi-6001/EQiH-6001

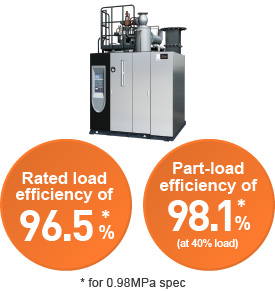

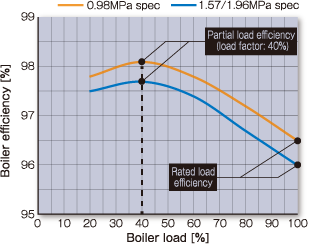

Industry #1 ultra-high efficiency

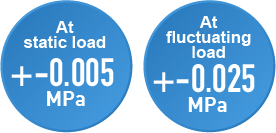

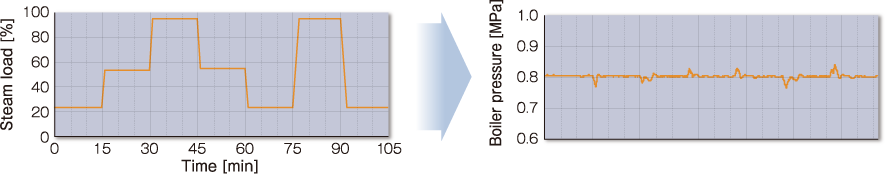

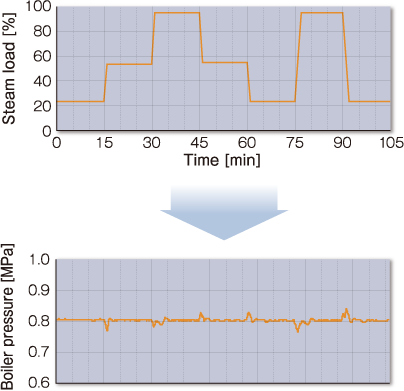

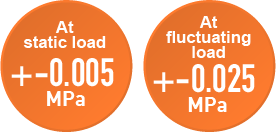

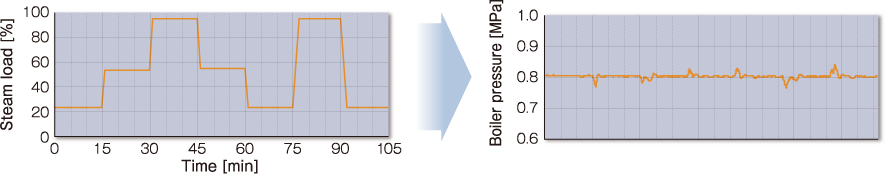

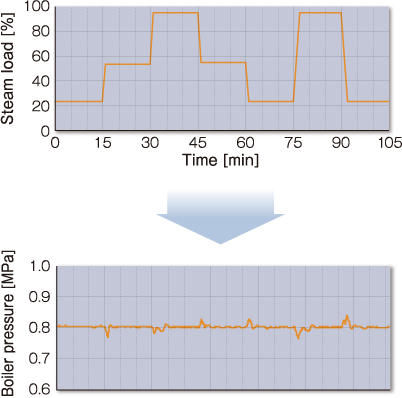

PI control (for pressure)

PI (Proportional-Integral) control keeps the boiler pressure stable regardless of whether the load is static or fluctuating.

Low environmental impact

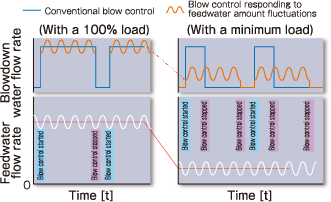

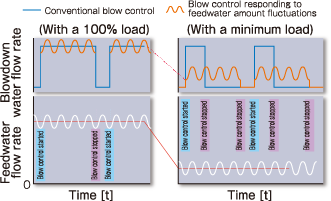

Blowdown control responsive to feedwater flow rate variations (Patent No. 5826539)

By increasing or decreasing the continuous blowdown flow rate as the feedwater flow rate changes, heat recovery of the blowdown water can be performed efficiently at any boiler load.

Super EQOS

EQi / EQO Series

| Model | Equivalent evaporation |

Fuel |

|---|---|---|

| EQO-2000 | 2,000 kg/h | Diesel Kerosene |

| EQi-2501 | 2,500 kg/h | |

| EQi-6001 / EQiH-6001 | 6,000 kg/h |

EQO-2000/EQi-2501

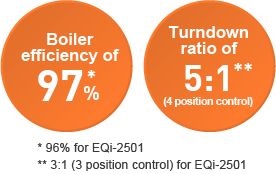

High efficiency

Inverter control

The blower fan speed is controlled by the inverter according to the boiler load to significantly reduce the blower power consumption at low load.

EQi-6001/EQiH-6001

Industry leading high boiler efficiency

PI control (for pressure)

PI (Proportional-Integral) control keeps the boiler pressure stable regardless of whether the load is static or fluctuating.

Low environmental impact

Blowdown control responsive to feedwater flow rate variations (Patent No. 5826539)

By increasing or decreasing the continuous blowdown flow rate as the feedwater flow rate changes, heat recovery of the blowdown water can be performed efficiently at any boiler load.